The piston bowls have also been worked over compared to a stock piston to promote a better swirl effect for a cleaner, more efficient burn in the combustion chamber. The combination of the forged piston and tool-steel wrist pin, with special coating to reduce wear and friction, should create a near indestructible product. Knowing that customers interested in a 4BT Stroker Kit would want to make as much horsepower as possible, ACD decided robust forged pistons would be the best option to ensure maximum strength and durability. While these upgrades can take the 4BT to all-new levels, we have to mention that because of its lack of cylinders and nearly identical operating rpm range, each piston is going to undergo a combustion cycle much sooner than that in a 6BT Cummins, so things like camshaft profiles and pump timing become critical for maximum efficiency at higher horsepower levels. To go along with major fuel upgrades, common cylinder head and turbocharger upgrades are required, but the aftermarket already has most of that covered as well with head studs, better valve springs, larger valves and even performance exhaust manifolds and camshafts built for four-cylinder diesels.

CUMMINS BIG CAM 350 PERFORMANCE MODS

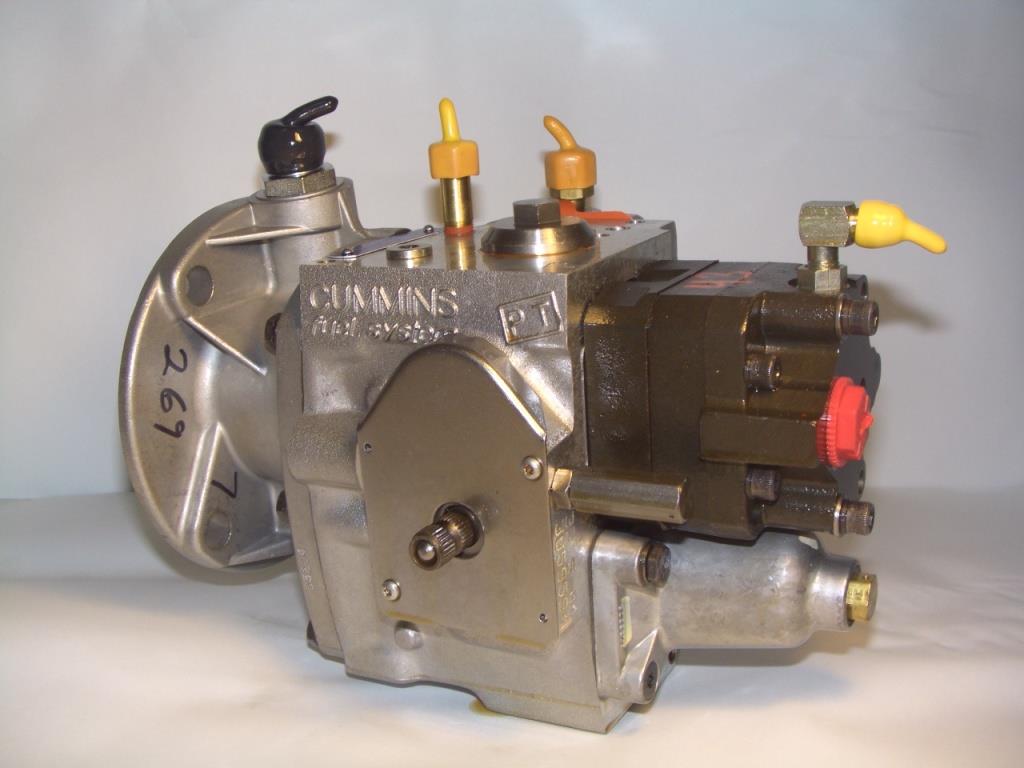

Fueling mods can be taken to the same extremes as with the 5.9L 12V Cummins: 12mm and 13mm pumps with laser-cut delivery valves, high-rev governor springs, full-travel rack plugs and modified injectors can all be used in the 4BT platform. Performance ModsĪs previously mentioned, the 4BT can easily be modified to produce higher than stock power levels when outfitted with the P7100 (P-pump).

An untrained eye may not notice much, but the design and material of the ACD connecting rods is far superior to the standard. The new H-beam rod (top right) is pictured with a factory 4BT rod (bottom right). These rods not only help increase engine stroke, they also provide unmatched durability to withstand extreme cylinder pressures from running massive power and torque through these engines. The new H-beam 4340 billet connecting rod (left) was engineered specifically for the 4BT engine. Starting with a one-of-a-kind connecting rod and piston design, ACD will soon offer complete Stroker Kits to pump up the power of 4BT platforms. It’s gained a reputation for its 4BT conversion projects and has developed new engine internals to take the average industrial 130-hp four-cylinder diesel to impressive performance heights. The simplicity of the mechanical injection system also helps make it an easy swap because there’s little to no wiring or electronics required.ĪCD Engines of Salt Lake City is a strong Cummins engine and parts dealer with years of experience in both the 6BT and 4BT platforms. We’ve seen 4BTs in everything from Jeeps to old-school rat rods. This, paired with the somewhat compact size of the 4BT, makes it a great candidate as a transplant engine for just about any vehicle. Because of these similarities, the 4BT Cummins has an extremely strong aftermarket, since many 5.9L 12V performance parts can be used in smaller 3.9L engines. But even these pieces are the same as the 6BT, just in an inline four-cylinder version. The major internal difference comes from the lack of two cylinders, which means two fewer journals on the crankshaft, a shorter camshaft, two fewer pistons in the injection pump, etc. Sharing virtually every internal and external piece with its big brother, the 5.9L 12V Cummins found in the 1989-98 Dodge Ram pickups, and coming as regular equipment in hundreds of commercial and industrial applications, parts availability, power potential, fuel mileage and the lack of electronics make it an easy go-to engine when it’s time to squeeze a diesel platform into the frame rails of just about anything. The 3.9L 4BT Cummins diesel engine has become an extremely popular platform for conversion projects throughout the past couple of years, and for good reason. pistons, connecting rods, injectors and valve-train design). The 4BT shares virtually all of its parts with its big brother, the 6BT (e.g.

CUMMINS BIG CAM 350 PERFORMANCE SERIES

The 4BT-which stands for “fourcylinder B series turbocharged”- was used mostly in midsize box trucks, agricultural equipment and small industrial vehicles, and is basically a smaller version of the popular 5.9L 12V Cummins found in 1989-98 Dodge trucks. But back in the day, it was Cummins that developed its own small diesel engine market with the 3.9L 4BT. Either way, these smaller V-6 and four-cylinder engines will be sticking around. Maybe the reasons for the boost are better highway fuel efficiency and the giant increase in torque offered by a diesel engine, but it’s probably an attempt to meet everincreasing CAFE (Corporate Average Fuel Economy) numbers. More and more manufacturers are offering new diesel power plants in ½-ton trucks, cars and midsize SUVs. THE POPULARITY OF diesel-powered vehicles here in the U.S.

0 kommentar(er)

0 kommentar(er)